Predictive maintenance is transforming the landscape of asset management, offering unprecedented opportunities for efficiency and cost savings. By leveraging advanced analytics and machine learning, organizations can anticipate equipment failures before they occur, thereby minimizing downtime and extending the lifespan of critical assets. This article delves into the intricacies of predictive maintenance, exploring its benefits, methodologies, and real-world applications.

Understanding Predictive Maintenance

Predictive maintenance is a proactive approach that uses data analysis tools and techniques to detect anomalies in equipment performance and predict potential failures. Unlike traditional maintenance strategies, which are either reactive or scheduled at regular intervals, predictive maintenance aims to address issues before they escalate into significant problems. This approach not only enhances operational efficiency but also fosters a culture of continuous improvement within organizations, as teams become more attuned to the health and performance of their assets. By utilizing predictive maintenance, companies can shift their focus from merely responding to equipment failures to actively managing and optimizing their assets, leading to a more strategic allocation of resources and improved overall performance.

The Evolution of Maintenance Strategies

Historically, maintenance strategies have evolved from reactive to preventive, and now to predictive. Reactive maintenance, often termed as “run-to-failure,” involves fixing equipment only after it breaks down. While simple, this approach can lead to unexpected downtime and higher repair costs. The unpredictability of equipment failures can disrupt production schedules, leading to lost revenue and customer dissatisfaction. As industries began to recognize the limitations of reactive maintenance, preventive maintenance emerged as a more structured approach. Preventive maintenance, on the other hand, schedules regular inspections and servicing based on time or usage metrics. Although more effective than reactive maintenance, it can still result in unnecessary maintenance activities and does not eliminate the risk of unexpected failures. This realization paved the way for predictive maintenance, which combines the best aspects of both strategies while addressing their shortcomings. By utilizing real-time data and advanced analytics, predictive maintenance allows organizations to make informed decisions about when and how to maintain their equipment, ultimately leading to a more efficient and cost-effective maintenance strategy.

How Predictive Maintenance Works

Predictive maintenance leverages a combination of sensors, data analytics, and machine learning algorithms to monitor equipment health in real-time. Sensors collect data on various parameters such as temperature, vibration, and pressure, which are then analyzed to identify patterns indicative of potential failures. This continuous monitoring creates a wealth of data that can be used to build a comprehensive picture of equipment performance over time. Machine learning models are trained on historical data to recognize these patterns and predict future failures with high accuracy. This allows maintenance teams to intervene at the optimal time, preventing breakdowns and reducing maintenance costs. Furthermore, the integration of cloud computing technologies enables organizations to store and analyze vast amounts of data without the need for extensive on-premises infrastructure. This not only enhances the scalability of predictive maintenance solutions but also facilitates collaboration among teams, as data can be accessed and shared across different departments and locations.

Benefits of Predictive Maintenance

The adoption of predictive maintenance offers numerous advantages, making it an attractive option for organizations across various industries. These benefits include reduced downtime, cost savings, and improved asset longevity. Additionally, predictive maintenance can enhance safety and compliance by ensuring that equipment is functioning correctly and adhering to regulatory standards. By proactively addressing potential issues, organizations can mitigate risks associated with equipment failures, such as accidents or environmental hazards. This proactive approach not only protects employees and assets but also helps organizations maintain their reputation and avoid costly fines associated with non-compliance. Moreover, the insights gained from predictive maintenance can inform strategic decision-making, allowing organizations to prioritize investments in new technologies or equipment upgrades based on the health and performance of their existing assets.

Reduced Downtime

One of the most significant benefits of predictive maintenance is the reduction in unplanned downtime. By predicting failures before they occur, organizations can schedule maintenance activities during planned downtime, ensuring continuous operation and minimizing disruptions. This strategic scheduling not only enhances productivity but also allows organizations to allocate resources more effectively, as maintenance teams can focus on high-priority tasks without the constant pressure of emergency repairs. Furthermore, the reduction in downtime can lead to improved customer satisfaction, as organizations are better equipped to meet production deadlines and deliver products on time. In industries where time is money, such as manufacturing and logistics, the ability to maintain operational continuity can provide a significant competitive advantage. Additionally, the data collected during predictive maintenance activities can be used to refine maintenance schedules and improve overall operational efficiency, creating a virtuous cycle of continuous improvement.

Cost Savings

Predictive maintenance can lead to substantial cost savings by preventing catastrophic failures and reducing the need for emergency repairs. Additionally, it optimizes the use of maintenance resources, ensuring that interventions are only carried out when necessary. This targeted approach to maintenance not only reduces labor costs but also minimizes the expenses associated with spare parts and equipment replacements. Organizations can also benefit from extended warranties and service agreements, as many manufacturers offer incentives for customers who implement predictive maintenance programs. Moreover, the insights gained from predictive maintenance can inform budgeting and financial planning, allowing organizations to allocate resources more effectively and prioritize investments in critical areas. By reducing the overall cost of maintenance, organizations can reallocate funds to other strategic initiatives, such as research and development or employee training, further enhancing their competitive position in the market.

Improved Asset Longevity

Regular monitoring and timely maintenance can significantly extend the lifespan of critical assets. By addressing issues early, predictive maintenance helps maintain equipment in optimal condition, reducing wear and tear and enhancing overall performance. This proactive approach not only extends the life of individual assets but also contributes to the overall sustainability of the organization. By maximizing the useful life of equipment, organizations can reduce their environmental impact and minimize waste associated with equipment disposal. Furthermore, the data collected through predictive maintenance can be used to inform future purchasing decisions, as organizations can identify trends in equipment performance and make more informed choices about which assets to invest in. This strategic approach to asset management not only enhances operational efficiency but also supports long-term sustainability goals, aligning with the growing emphasis on corporate social responsibility in today’s business landscape.

Implementing Predictive Maintenance

Implementing a predictive maintenance program requires a strategic approach, involving the integration of various technologies and the collaboration of cross-functional teams. The following steps outline the key components of a successful predictive maintenance strategy. It is essential for organizations to foster a culture of collaboration and communication among different departments, as successful implementation often relies on the input and expertise of various stakeholders, including maintenance personnel, data analysts, and management. By creating a shared understanding of the goals and benefits of predictive maintenance, organizations can ensure that all team members are aligned and committed to the program’s success.

Data Collection

The first step in implementing predictive maintenance is the collection of relevant data. This involves installing sensors on critical equipment to monitor parameters such as temperature, vibration, and pressure. The data collected by these sensors forms the foundation for predictive analytics. Organizations should also consider integrating data from other sources, such as maintenance logs, operational data, and external factors like environmental conditions, to create a more comprehensive view of equipment health. This holistic approach to data collection enables organizations to identify correlations and trends that may not be apparent when analyzing data in isolation. Additionally, organizations should establish protocols for data management and storage to ensure that the collected data is easily accessible and can be analyzed effectively. By investing in robust data infrastructure, organizations can enhance their predictive maintenance capabilities and drive better decision-making.

Data Analysis

Once the data is collected, it needs to be analyzed to identify patterns and anomalies. Advanced analytics tools and machine learning algorithms are used to process the data and generate insights into equipment health. This analysis helps in predicting potential failures and determining the optimal time for maintenance. Organizations should also consider implementing visualization tools to present the data in a user-friendly format, making it easier for maintenance teams to interpret the results and take action. By providing clear and actionable insights, organizations can empower their teams to make informed decisions and prioritize maintenance activities effectively. Furthermore, organizations should continuously refine their data analysis processes, incorporating feedback from maintenance personnel and leveraging new technologies as they emerge. This commitment to continuous improvement will enhance the accuracy and reliability of predictive maintenance efforts over time.

Integration with Maintenance Management Systems

To ensure seamless implementation, predictive maintenance should be integrated with existing maintenance management systems. This integration allows for the automatic scheduling of maintenance activities based on predictive insights, streamlining the maintenance process and improving efficiency. Organizations should also consider integrating predictive maintenance with other enterprise systems, such as inventory management and supply chain systems, to create a more cohesive operational framework. This holistic approach to integration enables organizations to optimize their maintenance processes and enhance overall operational efficiency. Additionally, organizations should invest in training and support for personnel to ensure that they are equipped to leverage the full capabilities of the integrated systems. By fostering a culture of continuous learning and improvement, organizations can maximize the benefits of predictive maintenance and drive long-term success.

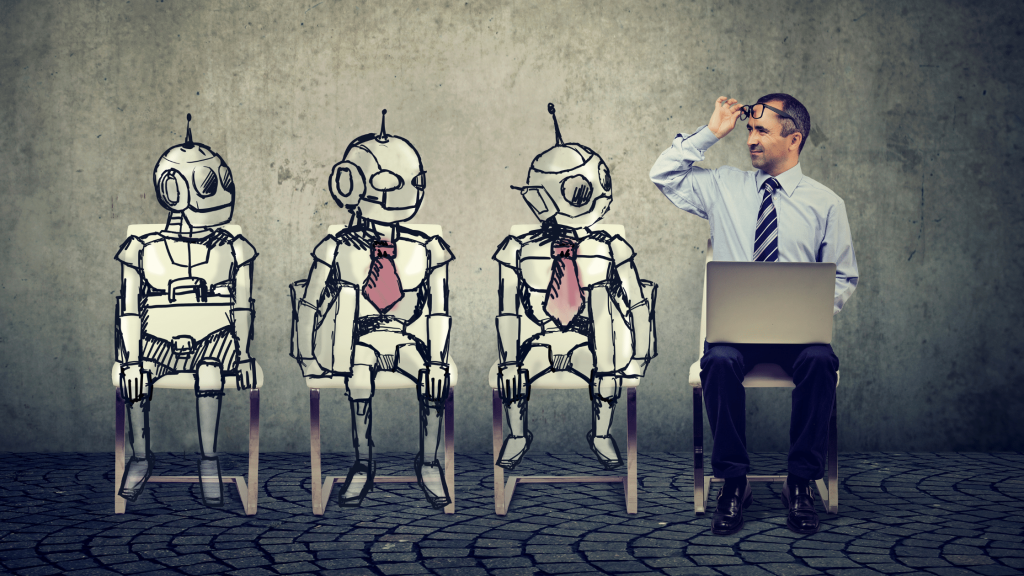

Challenges and Considerations

While predictive maintenance offers numerous benefits, its implementation is not without challenges. Organizations need to consider factors such as data quality, integration complexity, and the need for skilled personnel to manage and interpret predictive analytics. Addressing these challenges requires a proactive approach and a commitment to continuous improvement, as organizations must be willing to adapt and evolve their strategies in response to changing circumstances and emerging technologies.

Data Quality

The accuracy of predictive maintenance relies heavily on the quality of the data collected. Poor data quality can lead to incorrect predictions and ineffective maintenance interventions. Therefore, it is crucial to ensure that sensors are properly calibrated and maintained to collect accurate data. Organizations should also establish data governance policies to ensure that data is consistently collected, stored, and analyzed according to established standards. This commitment to data quality not only enhances the effectiveness of predictive maintenance but also supports broader organizational goals related to data-driven decision-making. Furthermore, organizations should consider implementing regular audits and reviews of their data collection processes to identify areas for improvement and ensure that they are leveraging the full potential of their data assets.

Integration Complexity

Integrating predictive maintenance with existing systems can be complex and time-consuming. Organizations need to ensure that their maintenance management systems are compatible with predictive analytics tools and that data flows seamlessly between different systems. This may require investing in new technologies or upgrading existing systems to facilitate integration. Additionally, organizations should consider the potential impact of integration on existing workflows and processes, as changes may require retraining personnel and adjusting operational procedures. By taking a strategic approach to integration, organizations can minimize disruptions and ensure a smooth transition to predictive maintenance. Furthermore, organizations should prioritize collaboration among IT, maintenance, and operational teams to ensure that all stakeholders are aligned and working towards common goals.

Skilled Personnel

Implementing and managing a predictive maintenance program requires skilled personnel with expertise in data analytics and machine learning. Organizations may need to invest in training or hiring specialists to ensure the successful implementation and ongoing management of predictive maintenance. Additionally, organizations should foster a culture of continuous learning and development, encouraging employees to stay current with emerging technologies and best practices in predictive maintenance. By investing in their workforce, organizations can enhance their predictive maintenance capabilities and drive long-term success. Furthermore, organizations should consider establishing partnerships with educational institutions or industry organizations to access training resources and stay informed about the latest trends and developments in predictive maintenance.

Real-World Applications of Predictive Maintenance

Predictive maintenance is being adopted across various industries, demonstrating its versatility and effectiveness in different contexts. The following examples highlight some of the real-world applications of predictive maintenance. These case studies illustrate how organizations have successfully implemented predictive maintenance strategies to enhance operational efficiency, reduce costs, and improve asset management.

Manufacturing

In the manufacturing industry, predictive maintenance is used to monitor the health of critical machinery such as CNC machines, conveyors, and robotic arms. By predicting failures and scheduling maintenance activities during planned downtime, manufacturers can minimize production disruptions and reduce maintenance costs. For instance, a leading automotive manufacturer implemented a predictive maintenance program that resulted in a 30% reduction in unplanned downtime and a significant decrease in maintenance costs. This success was achieved by leveraging advanced analytics to monitor equipment health and optimize maintenance schedules. Additionally, the insights gained from predictive maintenance allowed the manufacturer to identify opportunities for process improvements and enhance overall operational efficiency. As a result, the organization was able to increase production capacity and improve product quality, ultimately leading to higher customer satisfaction and increased market share.

Energy Sector

The energy sector, particularly in power generation and oil and gas, relies heavily on predictive maintenance to ensure the reliability of critical assets such as turbines, compressors, and pipelines. Predictive maintenance helps in preventing catastrophic failures, ensuring continuous operation, and optimizing maintenance resources. For example, a major oil and gas company implemented a predictive maintenance program for its offshore drilling rigs, resulting in a 25% reduction in maintenance costs and a significant increase in operational efficiency. By utilizing real-time data from sensors and advanced analytics, the company was able to predict equipment failures and schedule maintenance activities proactively, minimizing disruptions to production. Furthermore, the insights gained from predictive maintenance allowed the company to optimize its asset management strategies, leading to improved resource allocation and enhanced overall performance.

Transportation

In the transportation industry, predictive maintenance is used to monitor the health of vehicles, aircraft, and railway systems. By predicting potential failures and scheduling maintenance activities proactively, transportation companies can enhance safety, reduce downtime, and improve operational efficiency. For instance, a major airline implemented a predictive maintenance program for its fleet of aircraft, resulting in a 20% reduction in maintenance costs and improved on-time performance. By leveraging advanced analytics to monitor aircraft health and predict potential failures, the airline was able to optimize its maintenance schedules and reduce the frequency of unscheduled repairs. This proactive approach not only enhanced safety but also improved customer satisfaction, as passengers experienced fewer delays and cancellations. Additionally, the insights gained from predictive maintenance allowed the airline to make more informed decisions about fleet management and resource allocation, further enhancing its competitive position in the market.

The Future of Predictive Maintenance

The future of predictive maintenance looks promising, with advancements in technology and increasing adoption across industries. Emerging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics are expected to further enhance the capabilities of predictive maintenance, making it an integral part of asset management strategies. As organizations continue to embrace digital transformation, predictive maintenance will play a crucial role in driving operational efficiency and improving overall performance.

Integration with IoT

The integration of predictive maintenance with IoT devices allows for real-time monitoring and analysis of equipment health. IoT devices can collect vast amounts of data from various sensors, providing a comprehensive view of equipment performance and enabling more accurate predictions. This real-time data collection not only enhances the accuracy of predictive maintenance but also allows organizations to respond more quickly to potential issues. For example, a manufacturing company that integrated IoT devices into its predictive maintenance program was able to reduce its response time to equipment failures by 50%, significantly minimizing downtime and improving overall operational efficiency. Furthermore, the integration of IoT with predictive maintenance enables organizations to leverage advanced analytics and machine learning to identify trends and patterns in equipment performance, leading to more informed decision-making and improved asset management strategies.

Advancements in AI and Machine Learning

Advancements in AI and machine learning are expected to enhance the accuracy and reliability of predictive maintenance. These technologies can analyze complex data sets, identify subtle patterns, and make more accurate predictions, further improving the effectiveness of predictive maintenance. As AI algorithms continue to evolve, organizations will be able to leverage these advancements to enhance their predictive maintenance capabilities and drive better decision-making. For instance, a leading technology company implemented an AI-driven predictive maintenance program that resulted in a 40% reduction in maintenance costs and a significant increase in equipment reliability. By utilizing advanced machine learning algorithms to analyze historical data and predict potential failures, the company was able to optimize its maintenance schedules and improve overall operational efficiency. This success highlights the transformative potential of AI and machine learning in the field of predictive maintenance, as organizations increasingly turn to these technologies to enhance their asset management strategies.

Big Data Analytics

Big data analytics plays a crucial role in predictive maintenance by processing and analyzing large volumes of data collected from various sources. This analysis provides valuable insights into equipment health, helping organizations make informed maintenance decisions and optimize their maintenance strategies. As organizations continue to generate and collect vast amounts of data, the ability to harness this information effectively will be critical to the success of predictive maintenance initiatives. For example, a leading telecommunications company implemented a big data analytics solution that enabled it to analyze data from thousands of network devices in real-time. This capability allowed the company to identify potential issues before they escalated into significant problems, resulting in a 30% reduction in network downtime and improved customer satisfaction. By leveraging big data analytics, organizations can enhance their predictive maintenance capabilities and drive better decision-making, ultimately leading to improved operational efficiency and increased competitiveness.

Conclusion

Predictive maintenance is revolutionizing asset management by enabling organizations to anticipate and address equipment failures before they occur. By leveraging advanced analytics and machine learning, predictive maintenance offers numerous benefits, including reduced downtime, cost savings, and improved asset longevity. While its implementation comes with challenges, the potential rewards make it a worthwhile investment for organizations across various industries. As technology continues to advance, predictive maintenance is set to become an integral part of asset management strategies, driving efficiency and cost savings in the years to come. By embracing predictive maintenance, organizations can position themselves for success in an increasingly competitive landscape, ensuring that they are well-equipped to meet the demands of the future.